Update 2015-03-01: by popular demand, IGES files for the top and bottom bulb mould. Use at your own risk.

- bulb Dated 2003-05-01. If you don't have a CAD program that opens these, you can use an online IGES viewer to view the files.

Our bulb moulds are CNC milled from aluminium and more than 15 bulbs have been made successfully from them.

Note that it could be useful to make the hole through which lead is poured in a little larger than shown on the plan.

Update 2004 July: Others experience with this CAD file is that with a cnc milled mould to these dimensions the bulb will come out slightly heavy (2600g) if you use pure lead(density 11.3 kg/dm3) as the material. We have used lighter (ca 10-10.5 kg/dm3) lead which includes other metals to make it slightly stronger.

Many persons have asked more about the bulb moulds and bulb making featured on my picture page so I decided to put the plans here.

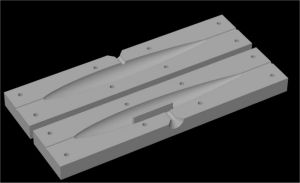

Based on the CAD representation on the left we were able to persuade a machinist to CNC mill moulds for us (right) in aluminium.

Update 2005 October: An anonymous reader sent me this pictures of his own CNC effort. The material is at present unkown and it is unkown if it can take the heat from molten lead...

Dear Anders,

I'm the Italian guy building a boat from the Laerke plan on your website. I've just pinted the hull. I promise you will have some pictures in few days! 🙂

Even if for this boat I already had the ballas, I came with some question...

If you use aluminum bulk for the moulds, the lead sticks on it? The separation of the ballast from the mould uses the different coefficient of thermal expansion of the two metals? Why the rod on the axis?

Hi Pietro,

If you send me some pictures I can publish them here.

Normally I think there is no problem with lead sticking to the aluminium moulds. We use a graphite paste on the moulds and there is no problem at all with sticking.

The brass rod in the middle gives extra stiffness to the bulb. With shorter bulbs it is not required but with a long bulb the ends will be very soft without the rod. Another option is to use a harder metal than pure lead, we've used 'printers-metal' (i.e. used for making letters when printing on paper). This alloy of lead has Antimon in it and makes it much harder so the rod would maybe be unnecessary.

Anders

can i ask what it cost to make your mould

Hi Alexander,

We got this mould made as an exchange: a guy made the mould for us, and we cast a number of bulbs for him. That's a great way to get a mould done, since a commercial machine shop would charge at least 500 eur for a mould I think.

If you follow my site you know that we are slowly upgrading our cnc machine. When the upgrade is done, hopefully in April-May or so, we'll probably be able to mill bulb and fin moulds ourselves - so get in touch later and we can discuss this further.

Anders

Hi,

Thinking of getting a friend to make a set of you lovely looking moulds. My friend asks what grade aluminium was used and also what are the internal profile dimensions? Thanks Dave

Hi David,

The grade of aluminium is not critical. Just use what you can find cheaply, or what your cnc-guy thinks machines easily.

For the internals of the mould, there's a more detailed plan here:

http://www.anderswallin.net/2005/06/simple-bulb-design/

The PDF contains an attached DXF which should be possible to import into most CAD packages.

AW