Curing epoxy mouldings typically requires elevated temperatures (+ 40Â to 70 C) for 4-12 h. Previously we have done this in a cardboard box with a car-heater continuously blowing hot air into the box. By adjusting the number and size of holes in the box the temperature can be crudely varied.

Here's an attempt to create a better heater with temperature control.

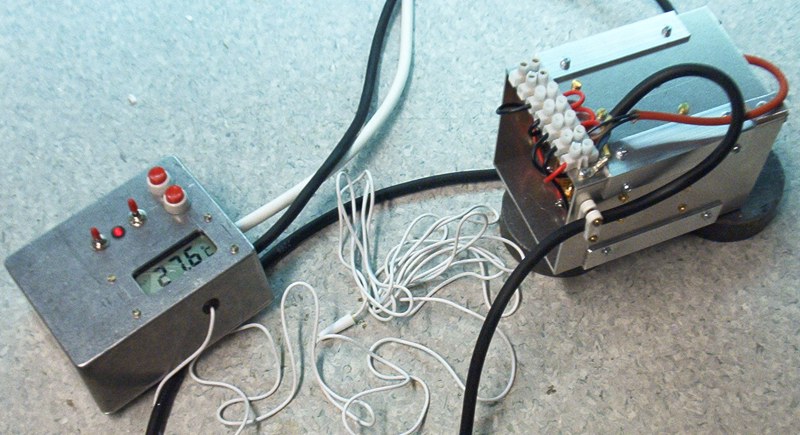

Temperature controller with display and input buttons on the left. White temperature sensor in the middle. 200 W heater-blower box on the right.

This is the controller box. The controller is based on a thermometer module which includes a display and a temperature sensor + control logic. I've wired some switches and buttons to the thermometer to allow setting of temperature limits.

This is the inside of the controller box. A 'wall-wart' type PSU (black, far left) provides 12 V for the relay (translucent case in the middle) and 1.5V by voltage division for the thermomenter (we see the backside of the display at the top). The part of the circuit I had to come up with myself was very simple, just an NPN transistor that takes the 1.5V control signal from the thermometer and allows driving of the relay coil. There's also a LED that indicates whenever heating is on. 230 VAC enters (white wire) and exits after relay (black wire) to the right.

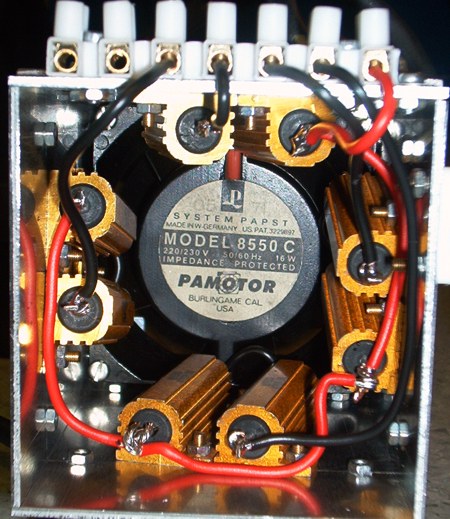

A somewhat improvized heating element. A 230VAC 80x80 mm fan sits at the back of the box and blows air over eight power resistors sized to dissipate about 50 W per box side. That makes for a total heating power of 200 W which can be throttled down by disconnecting 0-6 resistors at the connector strip (top)

During the next moulding session we will see how well this controller-heater combo works. For hull/deck mouldings we want to keep a temp of only about + 40 to 50 C. For fins and rudders we have aluminium moulds which means we can test how high this heater can heat. Hopefully more to follow...

Olof tells me this device will be really useful in the wine cellar during the winter also ....

Â

Â

Â

DISCLAIMER: Do not work with lethal mains power unless you know what you are doing ! If you copy this design you do so at your own risk.

Â

Nice device! I would also integrate some sort of independent heatingsensor to cut off ...just in case. For my own -slowly progressing- project

I had far too low temps in my homeshop this winter/spring, so I made a curingbox too. I made a box from 20mm(2x10) foamboard.The heat

from old 200w hairdryer. Tempcontrol old 30-90 degrees washingmaschine thermostate. Safety: 90 degrees cutoff from washingmaschine. It works real fine.The temperature cycles about 5 deg in the 50 region with heating running one minute every five minutes. I had to cover the sensortube under a piece of metal to dampen the on/off freq. To monitor the temp I use a digital -50 - 300C termometer , but a cheap stowe

one could do.

The box is also very usefull for heating epoxy and glass/carbon to working temperatures in a cold/damp shop.

Jens DEN