Jari has almost completed the mechanical part of our cnc-mill upgrade: fitting a new 500 mm X-travel table on linear rails and installing ballscrews.

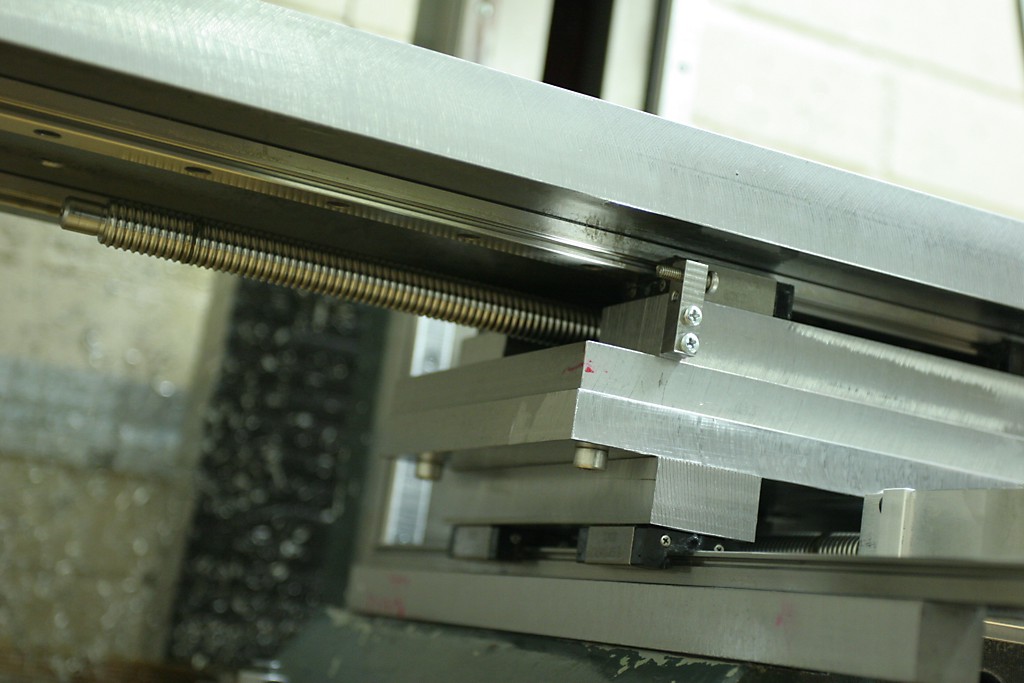

The bearing holders for the free end of the ballscrews are not done yet, so in the pictures the free ends are ...free. Here you also see how everything is assembled: the Y-axis ballscrew and rails sit on the base of the machine, there's a two-part saddle plate on the Y-bearing blocks, and the X-rails/ballscrew attach to the underside of the table.

The new table assembly is a bit higher than the old table which means that Z-travel is restricted. We also need to make a slot in the Y-axis saddle plate to allow for the axis coupler to slide under it. Now Y-travel is only about 150 mm, but it should go up to 200 with this mod.

Initial tests with the old stepper motors and temporary crude axis couplers are promising. We have elminated backlash, and friction is down a lot meaning higher velocities and accelerations are possible. Can't wait to see how this thing moves with the servos!

One thought on “Opti-BF20 on rails”