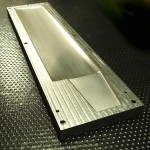

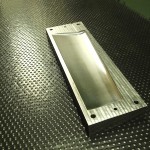

With the servo-upgrade of the cnc-mill complete we are now beginning to run the kind of jobs that weren't previously possible. Stepper motors simply don't give the kind of 3D contouring capability and reliability for running 3-4 hour finish jobs like these. The finmould is finished with a 6 mm ball-nose cutter.

Jari made these moulds in steel, but it's possible to cut them in aluminium too. The fin mould here has a NACA 0010 section and the rudder has a thicker NACA 0015 section. With the precision that cnc-cutting provides we hope that the fin can come out of the mould quite complete and fit a cnc-cut finbox/bulb without much manual fitting.

We can produce fin, rudder, and bulb moulds in steel or aluminium on a small scale. Get in touch by email or by commenting below if you are an interested IOM-builder.

Can you cnc M foil mould for me?

I am in Melbourne Australia.

Lincoln

Hi Lincoln,

The longest movement of the machine is around 500mm along the X-axis. If you want a mould longer than that we would have to cut one end of the mould first and then re-position the mould to cut the other end. There will be a visible seam between these two parts but it will likely be below 0.1 mm in height and have nor effect on performance.

If you send me a design in DXF or IGES format I can look at it and estimate time/cost. We ask around 500 euros for an IOM fin mould so a longer one would be slightly more.

Anders