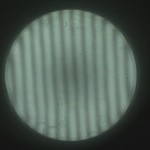

Polishing is hard work compared to fine grinding. There is much more friction between the lap and the mirror - it's nice to take a break after 15 to 20 minutes of polishing. Possibly due to insufficient pressing our mirror started to polish at the outer edge first. We did about 2 hours of polishing the first evening. Today we started with hot-pressing, i.e. leaving the lap and mirror under hot water for a while and then pressing the two against each other to achieve good contact. After about 1 hour today we did a first Ronchi test, which clearly shows the less well polished spot in the middle. One more hour of polishing and we are up to about 4 h in total. There's still a hint of the less well polished area in the middle. Looking at the Ronchi test the overall shape of the mirror is roughly spherical as it should.

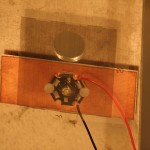

Our Ronchi tester consists of a wooden mirror stand made from plywood with three long M6 bolts to hold the mirror. We're using an LED as a light source, and the 100 lines per inch grating is printed on an overhead-slide with a laser printer.

The radius of curvature is roughly 288 cm indicating a focal length of 144 cm which would make for a focal ratio of F/6.

One thought on “Polishing and Ronchi testing”