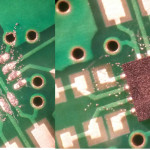

I soldered some quite small SMD parts today using solderpaste and a Hakko FR-810 hot-air rework station.

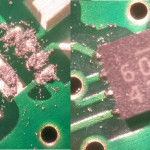

The smaller part is an 8-pin 2.0 mm x 2.0 mm MLF-8 packaged logic buffer. 0.5mm pin pitch. See page 17 over here.

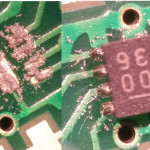

The large part is a 14-pin 2.5mm x 2.5mm UQFN-14 packaged op-amp. Also 0.5mm pin pitch. Dimensions and footprint available here.

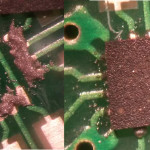

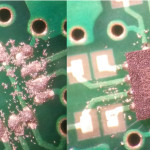

I had to rework one chip manually with a soldering iron because I applied too much solderpaste. Otherwise things seems to have gone smoothly. I applied the solderpaste manually using two disposable scalpels - getting the amount and location of solderpaste right took quite a long time. I then positioned the chip on the footprint and applied hot air. On the FR-810 I used the lowest air-flow setting "1" and a temperature of 290 C. When the solderpaste melts it pulls the chip into position if things go well.

To supply an adequate amount of solderpaste using disposable scalpels is painful work! There is another method. Using a normal soldering iron, put and adjust the amount of solder on the pads (Of course the solder will melt and become solid on the pads). Dope flux to both pads and IC pins, dry those slightly, put the IC on the pads, and use your FR-810 to melt the solder again. (To apply the hot air vertically, I strongly recommend you to use 'Rework fixture' C1392B http://www.hakko.com/english/products/search_result.php?k=C1392B .)

If you have a PCB milling machine (LPKF Protomat S91?), you can also make a home-made PCB stencil using laminate films (e.g. http://www.amazon.com/Iris-laminate-film-pieces-LZ-A4100/dp/B000O76S2S/ref=sr_1_1?s=home-garden&ie=UTF8&qid=1451471928&sr=8-1&keywords=iris+ohyama+Laminate). Once attach the film on a flat board, peel it after the milling, spray some flux remover and remove its adhesive. 0.5mm pitch is a little bit difficult, but you can use it as a simple and throwaway PCB stencil.

OK, thanks for the suggestions!

If I use the method of first applying solder with a normal soldering iron, does it make a difference if I use solder-paste or just normal solder-wire from a spool? Does the solder-paste work better in step two with the hot-air gun compared to normal solder?

thanks!

Anders

>does it make a difference if I use solder-paste or just normal solder-wire from a spool?

>Does the solder-paste work better in step two with the hot-air gun compared to normal solder?

Maybe it does not make any differences. The solder-paste is a mixture of small solder balls, flux, and other additive, etc. And be careful, putting a hot soldering iron into the solder-paste may make small explosion.