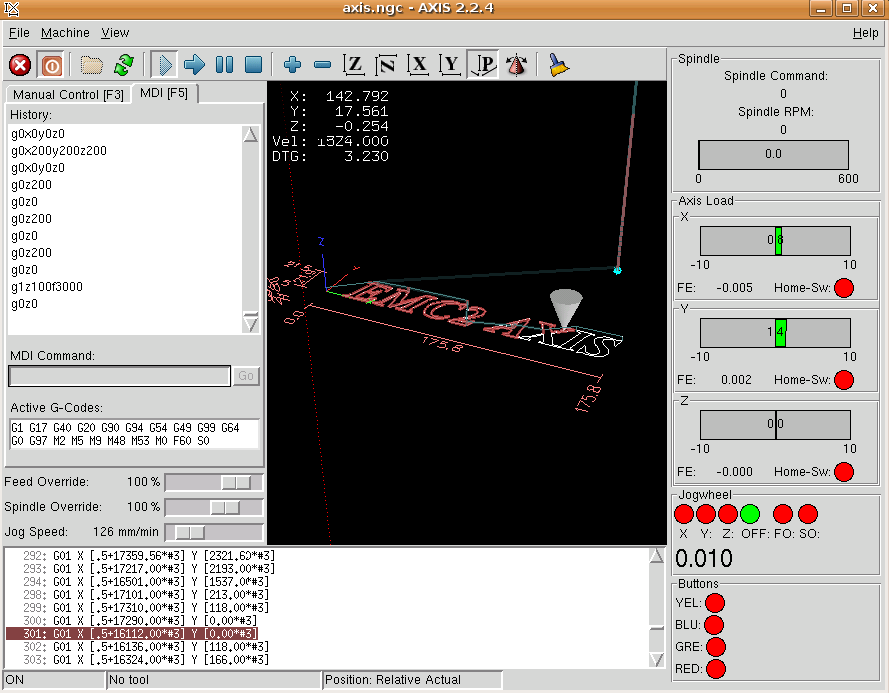

The servos are now almost ready to go on the mill. Some dry-running of EMC2, the servo electronics, and the VFD today. I've made this pyVCP panel for AXIS which displays the commanded and actual spindle RPM, the spindle current (in some uncalibrated unit), the PID outputs and following errors for X/Y/Z. The jog-pendant box shows the mode of the jogwheel (X-jog, Y-jog, Z-jog, Off, Feed-override, Spindle-override), and the jog-increment (0.01 mm above). The four pendant buttons are now wired to turn on/off the coolant (blue button), to start the spindle forward or stop it (yellow button), to step through the program (green button), and to pause/resume the program (red button).

A video of the setup.

0:00 Actors, in order of appearance: EMC2, jog-pendant, electronics box, limit-switch box, X/Y/Z servos, VFD, Spindle motor.

0:30 Running a program. Load-meters. Rotating servos. Rotating spindle. Note professional mount and axis-coupler for spindle-encoder. The encoder will eventually be mounted on the other end of the motor.

1:30 Load-monitor demonstration. Running the machine from (300,300,300) to (0,0,0) with a rapid move (6000mm/min or around 2400 RPM on the servo shaft) and watching the bar-graphs show the commanded PWM to the amps.

It's best to store all the working config files here in case of disk crashes or other data loss:

- INI

- HAL (I should write a post about everything that is in this file some day)

- pyVCP

- postgui-HAL