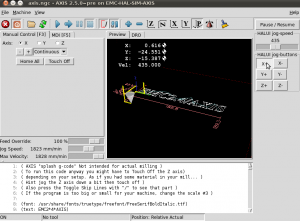

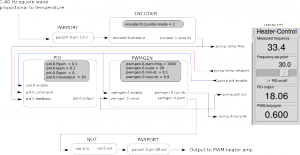

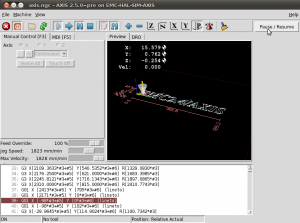

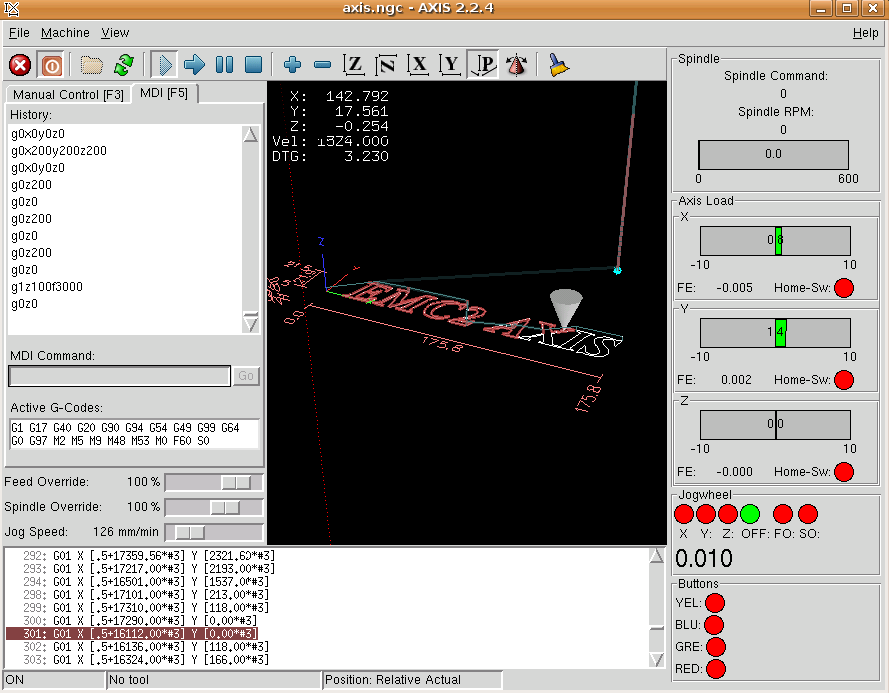

After some initial tuning we did three test-prints today of a 10x10mm square, 30 layers, raising the z-axis by 0.5mm for each layer. We tried to set it up so that when the X or Y-axis moves 10mm, the extruder A-axis should also move 10 units. The way it is set up right now it might be extruding slightly too much plastic per mm. The maximum feedrate we tried was 600mm/min.

We printed the same geometry three times, here is the second try (in the first try the base/bed wasn't staying very fixed, so the print resembles the leaning tower of Pisa...)

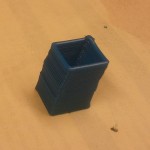

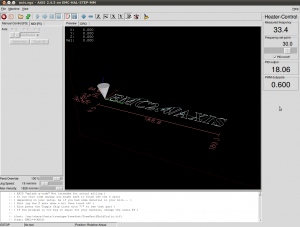

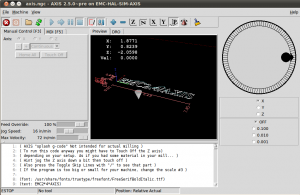

Here is the third try. Now we are moving the Z-axis +0.5 mm during the last Y-axis move. This is at 600mm/min.

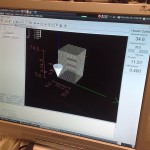

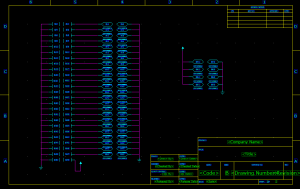

We were pretty happy with the print-quality so far, considering this is the first ever test of our extruder/xyz-table setup. Some tuning of how much plastic is extruded for each mm of xyz-feed, and perhaps a heated printing-bed, should improve the quality further. Next is learning to use one of the many STL to G-code CAM programs and filtering the G-code output so it is suitable for our EMC2 setup (the extruder is the A-axis, in absolute mode).

Update: Risto has more on this in his blog: ?http://risto.kurppa.fi/blog/2010/12/first-prints-with-reprap-the-open-source-3d-printer/