A bit of progress with the electronics cabinet for the lathe. Some components have been bolted to the back wall of the cabinet. From left to right: a Bonmet servo-drive for the main spindle servo, a Siemens VFD for the live-tool spindle motor, and to the right two Brushless PWM amps for the X and Z axis motors from pico-systems. Below these there are two 350W 48VDC switched-mode powersupplies. Today I made holes for two 220VAC 120 mm fans which blow air from both the left and right side into the cabinet directly on the heatsinks of the servo drives. There are plenty of holes in the bottom of the cabinet through which the air can exit.

Category: CNC

Rudder mould Rock

Lathe electronics

Most of the electronics I've ordered for the lathe has arrived by now. Still waiting for the servo-drive for the main spindle.

Bottom left are three switched-mode power supplies: 5V 3.5A (logic etc), 12V 3.3A (brushless amps, E-stop chain, etc), 24V 1.3A (spindle brake)

Bottom right are two Chinese 350W 48VDC 7.3A power supplies for the X- and Z- servos. Bought on e-bay from one of the Chinese sellers that has free worldwide shipping, and these were not caught by the local customs, so I paid around 28 euros/supply!

Mid row: on the left a Siemens Micromaster 420 0.37 kW VFD which will be used for a future live-tool spindle, and on the right two pico-systems brushless servo-amps.

Top: limit switches, Mesa 5I20 PCI-card, 180W Brushless servos for X and Z, CUI encoders, Amphenol connectors.

CUI Encoders

Digikey corrected their mistake and shipped The Real McCoy to me today.

Mesa electronics 5I20 fpga-card

This PCI-card with an FPGA and 72 I/O lines will be used to control the lathe.

$199 from Mesa electronics

MPG

Spindle servo encoder shaft

The 1.75kW spindle-servo for the lathe only has resolver and hall-feedback. So I need to mount an incremental encoder with index pulse on it myself. The rotor for the hall-sensors attaches to the main motor shaft with an M6 bolt. Here I'm making my own M6 bolt with a long 'head'/shaft that will extend outside the back lid of the motor. I cheated a bit by starting with a 0.5" rod which already had an internal M6 thread. An M6 set-screw will form the bolt-part of the shaft, and is also used here to hold the part in the lathe. This was then turned down to ca 11mm to fit the hall-rotor, and 8mm for the part of the shaft that extends outside the motor and to which the encoder will mount.

Encoders are on order from digikey so they should arrive next week.

By taking it slow and measuring a lot the 1949 Schaublin makes parts with tolerances approaching 0.01mm!

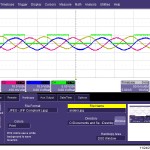

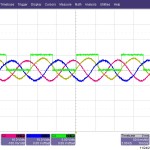

Spindle servo Hall-signals

Figured out the hall- and resolver-signals on the spindle servo today. There are two scope-pictures but the hall signal corresponding to the third phase is also OK, I just didn't save the screenshot. The pinout seems to be:

1: resolver a+

2: resolver a-

3: resolver b+

4: resolver b-

5: resolver c+

6: resolver c-

7: Hall A

8: Hall B

9: Hall C

10: +5V

11: GND

12: PE/case-ground

The Hall outputs require pull-up resistors, this test was with 1 kOhm resistors. If I install a normal A/B/Z encoder on the motor myself I should be able to drive it with a stock standard Brushless servodrive.

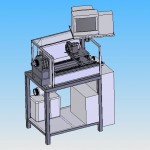

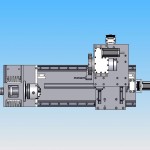

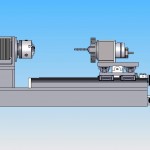

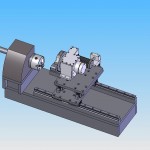

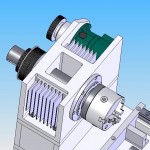

Lathe CAD Screenshots

Lathe Spindle and Z-rail measurements

(the dial indicator reads in metric, with 1um resolution)

radially the spindle chuck-flange shows ca 14-15 um of runout.

Axially there is more wobble, ca 20um.

The Z-rails are very accurately aligned in the X-direction, I measured ca 6um error.

Measuring in the Y-direction, there seems to be a 40-50um jump around 10cm from the chuck. I'm not sure if that is important, since the rail-blocks don't make contact with the rail top surface. I think I need a way of measuring this again with the machine assembled.