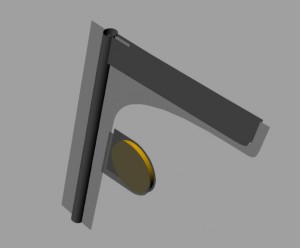

Update: here is Jari's "fork" design for the mast-partner:

The forward hole could be made a bit bigger so a 4mm acetal-rod with a small central hole for the jib-sheet will fit. There could be an M3 or M4 threaded hole added for the mast-ram, and finally some holes for a U-shaped bent wire which forms a deck-eye through which the no3 jib is sheeted.

Here's the glassfiber version I was first thinking about:

The way we mould the deck and hull in one go we don't get an overhanging foredeck which would support the mast. One solution is this kind of "mast partner" which is glued/bolted to the foredeck and provides sideways support for the mast. If the slot is made say 16 mm wide the mast will need a sleeve of metal/plastic that fits this 16 mm slot accurately. There is room for a ca 18-19 mm diameter thumbwheel(red) on the mast ram.

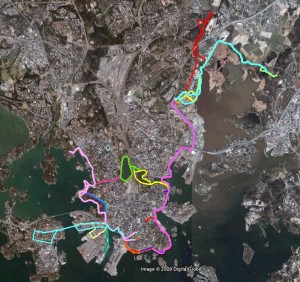

Here's a photo of a SAILSetc 10R (or M?) which uses this idea: