(click image for high-resolution version)

The current Noux Mk2 construction is obviously too difficult to put together. There are lots of separate mouldings that need to be fit and bonded to the hull, lot's of sanding, filling, and painting. So I'm trying to think of a simpler design that would be easier to build. With all the moulds and jigs ready my dream would be to spend one whole day on moulding: hull, deck, fin, rudder, etc. Go home and sleep/do other things while everything cures for a day or two, and then spend the next day bonding together the components. With about two full days of work I would hope to create a ~500 eur kit which can be handed to an intermediate to advanced IOM-skipper which he/she could then complete by adding fittings, radio, and rigs. Is this Utopia?

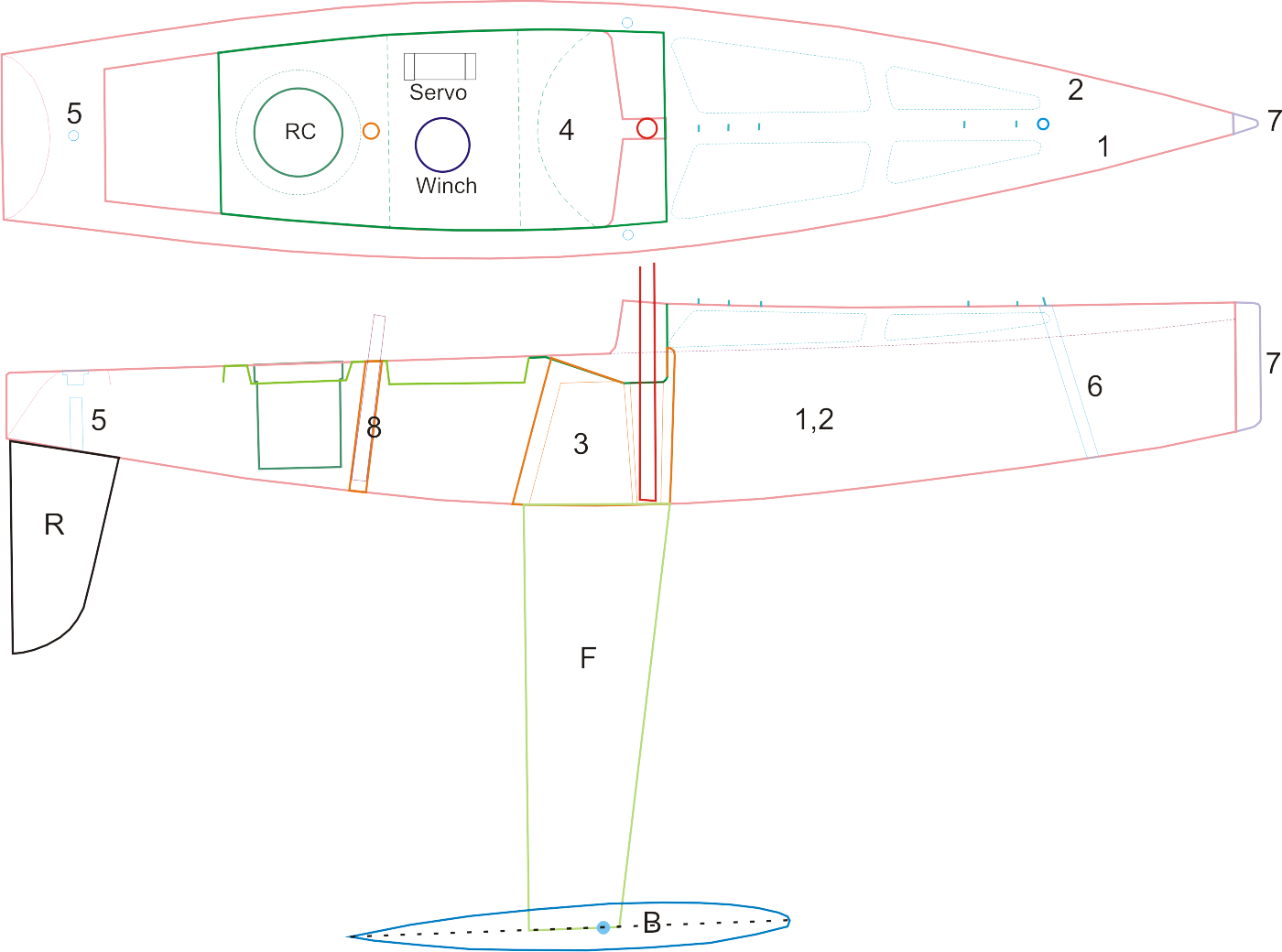

The Bantock/SailsETC style of construction (Topiko-ish drawing above) simplifies building somewhat. The two halves of the hull (1,2) are moulded separately and then joined. A separate fin/mastbox laminate (3) needs to be bonded into place while the hull is in a jig, to keep everything nice and straight. The foredeck comes 'for free' in the hull moulding process, but the aft deck (4) is a separate moulding. Here I've drawn a recessed flat part for mounting the winch and the servo, and a place for the 65mm RC-pot aft of the main-sheet post.

Then there are small bits and pieces like the rudder tube (5), the tube for the no1 rig (6), and the bow bumper (7).

Sails ETC sells a cheap plastic rudder (R), and some not-so-cheap fins (F). We can make bulbs (B) in lead by casting, or maybe in brass or steel by cnc-turning in the future.

I really feel the challenge is in components 1 through 4, the large mouldings that need to be accurately assembled, and apart from the finbox need to have a nice gelcoat outer finish. With the Topiko-style transom the two hull-halves (1,2) can't be assembled in the hull mould, so a separate hull mould without the inverted transom is needed. This assembly-mould/jig could also have a permanent hole for a dummy-fin that is put in place and aligns the separately moulded fin/mastbox (3). The aft-deck (4) would then be bonded in place with the help of strips of glassfiber plate glued to the underside of the hull-flange.

If I count the building tasks correctly I get something like this:

- Mould two hull-halves. (spray mould with gelcoat/paint, apply epoxy+2x125g glassfiber, trim glassfiber to mould-edge)

- Mould other components: deck, fin/mastbox, mainsheet-tube, no1-rig-tube, bumper (in silicone)

- Wait for everything to cure

- Assemble hull-halves in separate jig. bond together. Glue in fin/mastbox, Glue in deck (can this be done simultaneously with finbox?). Glue in rudder tube.

- Wait for everything to cure

- Finish by adding bits and pieces: open foredeck holes, glue in no1-rig tube, glue in mainsheet-post tube, attach bumper.

That's three tasks separated by curing-time. I'd be interested if anyone has some thoughts on this! Have I overlooked something big? Can this be simplified further?

I know some people have used closed-mould techniques with a pressurized balloon inside to mould complete boats in one go. But as there are no good descriptions of this online I'm not going to pursue that in the near future.