The latest IOM building activity in Finland: a group of builders in Turku have moulded a hull mould from the original Noux plug + designed their own deck plug and made a deck mould.

Continue reading Noux moulds

Category: IOM Building

Building a wooden Noux

Inspired by the drawings and design info available on my site, and by Michael Scharmers article on iom-nordic.org, Peter Trimmer (AUS) is putting together a wooden Noux. He sent me some pictures of his progress.

Here is the plug for the bulb turned out of wood. A mould around this from plaster will be made and the bulb will be cast in lead.

CNC Milling of MDF Plug

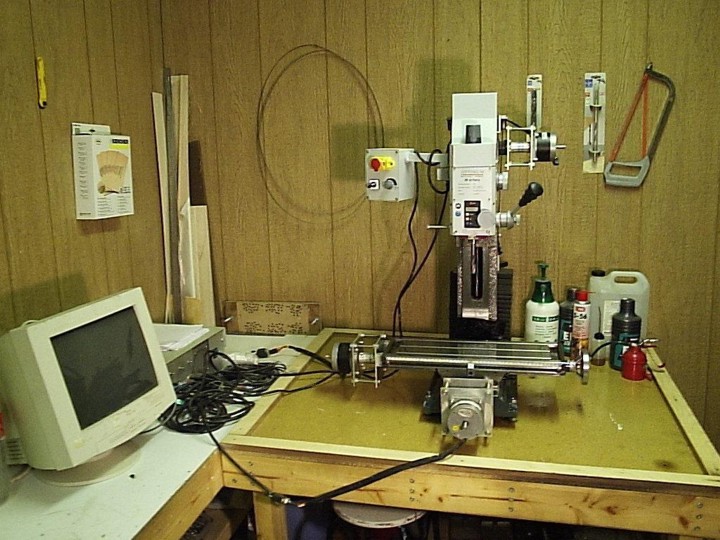

Jari Immanen is making a plug for a Marblehead. This is our homebuilt CNC machine. It's an Opti BF20 retrofitted with steppermotors. Geckodrives drive the steppers using the TurboCNC software.

Continue reading CNC Milling of MDF Plug

IOM Bulb Mould plans

Update 2015-03-01: by popular demand, IGES files for the top and bottom bulb mould. Use at your own risk.

- bulb Dated 2003-05-01. If you don't have a CAD program that opens these, you can use an online IGES viewer to view the files.

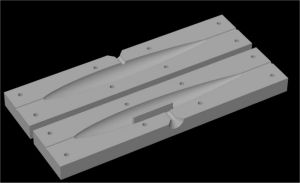

Our bulb moulds are CNC milled from aluminium and more than 15 bulbs have been made successfully from them.

Note that it could be useful to make the hole through which lead is poured in a little larger than shown on the plan.

Continue reading IOM Bulb Mould plans

Making a Bulb

A short description of how we cast bulbs.

Desing your bulb with a CAD program. Our bulb has a round cross section with a NACA 0010-34 profile.

Length 355 mm

Max diameter 38 mm

supported by solid 5mm brass rod

Target weight 2400 g

See also: Simple Bulb Design and IOM Bulb Mould Plans

Find someone who owns or has access to a suitable CNC Mill and talk very nicely with him/her(commercial alternatives are likely to be very expensive, estimate ca 1000 EUR or USD). Hopefully the end product will look something like this. Molds are from solid aluminium and the final milling pass was made using a 5 mm ball nose mill.

Go outside. Heat up a suitable amount of lead using a gas-stove (old, not in kitchen use !). The temperature of the flame is just enough to melt the lead so the temp. outside needs to be at least 15 C or so. Put the mold on the stove also, the lead will pour in and fill the mold much better if it is warm.

Build yourself a stand for the mold and figure out how you're going to be pouring the lead etc...

We use a gas flame to keep the input hole to the mold warm.

Now it's time to pour in the lead. Be very careful... pour until the mold is full. Leave the gas flame on and you will notice that as the lead cools it contracts and after a while you can pour some more.

Let the mold cool down for at least 30 minutes or so. A metal handle system helps when moving the mold around.

Loosen the bolts, open the mold and carefully tap with a small hammer and the bulb will come out.

The IOM class rules limit the weight of the keel (fin+bulb) to 2500g. A typical fin weighs maybe around 100-130 g so the target weight of a bulb should be around 2400g. This individual seems to weigh around 2430g which is OK.

If everything went well the final product should look something like this. We have had some problems with the lead not filling the mold perfectly but this has been solved by properly heating the mold before pouring and by adjusting the tilt angle of the stand/jig. The color is quite shiny in the beginning but as the lead oxidizes it will go back to the more familiar dark gray. Some have suggested coating the bulb with clear epoxy to keep this shiny look.

Update 2005 October:

Our largest bulb order to date ! 12 bulbs in one go. Had to build some wooden frames to ease the transportation. The overlong brass rods make the bulbs easier to tranport.