The parts of the plug have been glued together, painted, and sanded. We should be ready to lay up the moulds in a few weeks.

Category: Model Yachting

Pikanto MDF plug

The final MDF piece for the plug was milled today.

MDF plug pictures

The first half of our Pikanto plug is now milled. The other half will be done next weekend - and then we have a lot of painting and sanding to do before laminating moulds.

Milling MDF

More plug milling

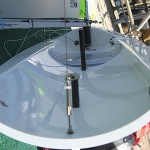

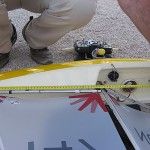

The model yacht plug we're making is milled in three stages. First a rough-cut, then a finish-cut which cuts the plug 1 mm undersize. Then it's coated with a thick layer of tooling gelcoat. What you see above is the final milling pass where the gelcoat is cut down to the final shape. This way we're hoping the final plug will require a minimum of painting/sanding before use.

Lester Gilbert has some new Pikanto pictures on his site. Eventually this project will produce boats like that, but with a deck which is simpler to mould, and with a process we hope to streamline as much as possible.

Milling MDF

Jari is making plugs for our latest IOM-project, and he posted two new videos:

Rough milling:

Finish milling:

The 1000 mm long hull plug will be made from a left and a right half, and each half consists of three parts. This is the first part from the bow to around 300mm.

Styyra 2008

The annual newsletter of the Finnish radio-sailors is out today:

Wave goodbye, wish me well

FIN-43, my current Noux-design IOM, is packed and ready for shipping to its new owner next week. I made a holder for the bulb from tube-clamps, and disassmbled the rigs today. Everything fits nicely into my 110x30x26 cm boat box.

The plan for 2009 is to cnc-mill plugs and make moulds for a variant of Pikanto, Graham Bantock's latest design. It's important to use time and effort on good design and good moulds. I want the boat and the components to come out of the moulds almost ready to use. Keep it simple stupid. CAD-design time and time on the cnc-mill is cheap, hours spent moulding and hand-building are expensive (for me anyway). More about that later. It also looks like we will be milling a new set of bulb, fin, and rudder moulds in December-January. We're happy to mill moulds for other people too, but most people don't answer the second email where I tell them a fin-mould costs 500 euros (which we think is reasonable).

IOM sail camera videos

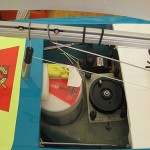

Looks like the mast bends to leeward at the middle, while the top of the mast stays in place. I don't think that's a good thing. Should try lower shroud attachment point and maybe shorter spreaders.

Remember to turn up the sound so you hear the wind, water, and the RMG winch! Also try these in higher quality by going to youtube and clicking "watch in high quality".

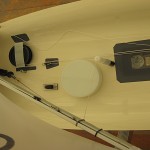

Here's how the camera looks on the foredeck:

IOM Euro pictures from Dubrovnik

Pictures by Eero Laurila and Olle Martonen from the 2008 IOM European Championships last week in Durbovnik, Croatia.