Kiilto B3 glue with 15mm x 15mm triangle-profile in the corners. Using a helper-profile with a plastic release-film worked quite well for clamping.

Category: woodworking

More laser cutting

Laser cut plywood test-project: a 2V geodesic sphere, diameter 200mm. Next is sanding the triangles a bit and then figuring out how to connect them neatly together.

Torsion-box workbench with parfguide hole-pattern

(Built a few months ago, but better blog late than never..)

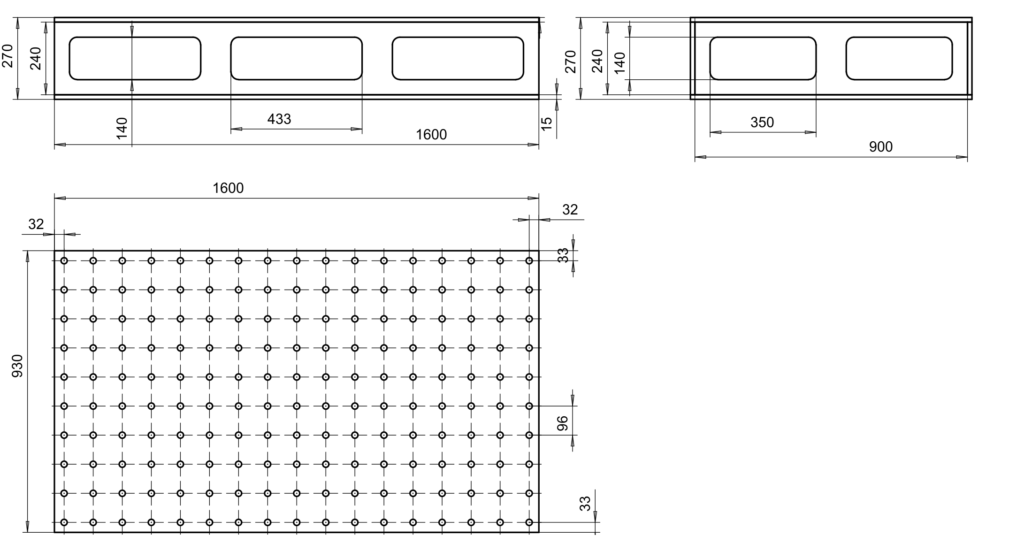

Here's a 1600mm-by-930 mm workbench built from two sheets (1220mm x 2440mm, 4-by-8 metric feet) of 15mm plywood. It's a torsion-box design with the top and bottom sheets separated by 240mm. The sides have rounded openings that create storage-bays for tools etc. The top has 20mm diameter holes drilled using the parfguide-system (it uses pythagoras 3-4-5 triangles to get the holes reasonably accurately positioned). The hole-grid is 10x17 so there are 170 holes in total. Assembled using pocket-hole screws.

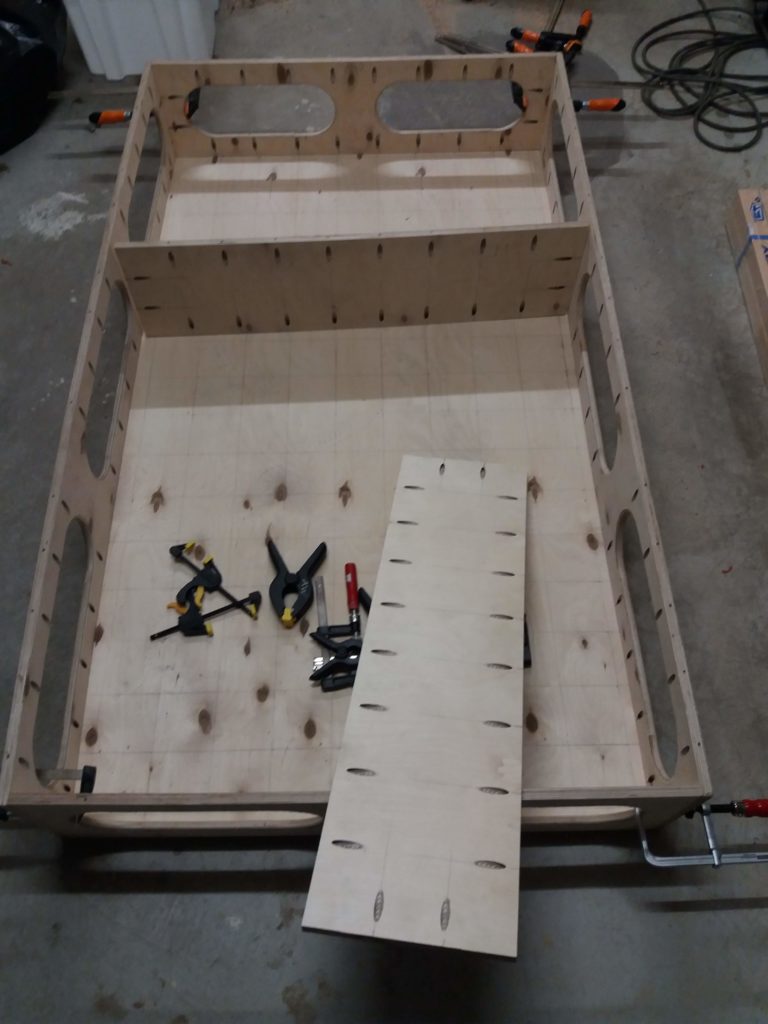

Parts cut and pocket holes drilled.

The middle dividers don't have rounded openings. For more stiffness maybe lengthwise dividers would be good also?

Assembled torsion-box, without top

Gluing 2x4s for the legs

Stand from 2x4s

Torsion-box on stand, before drilling holes.

Storage-bay opening.

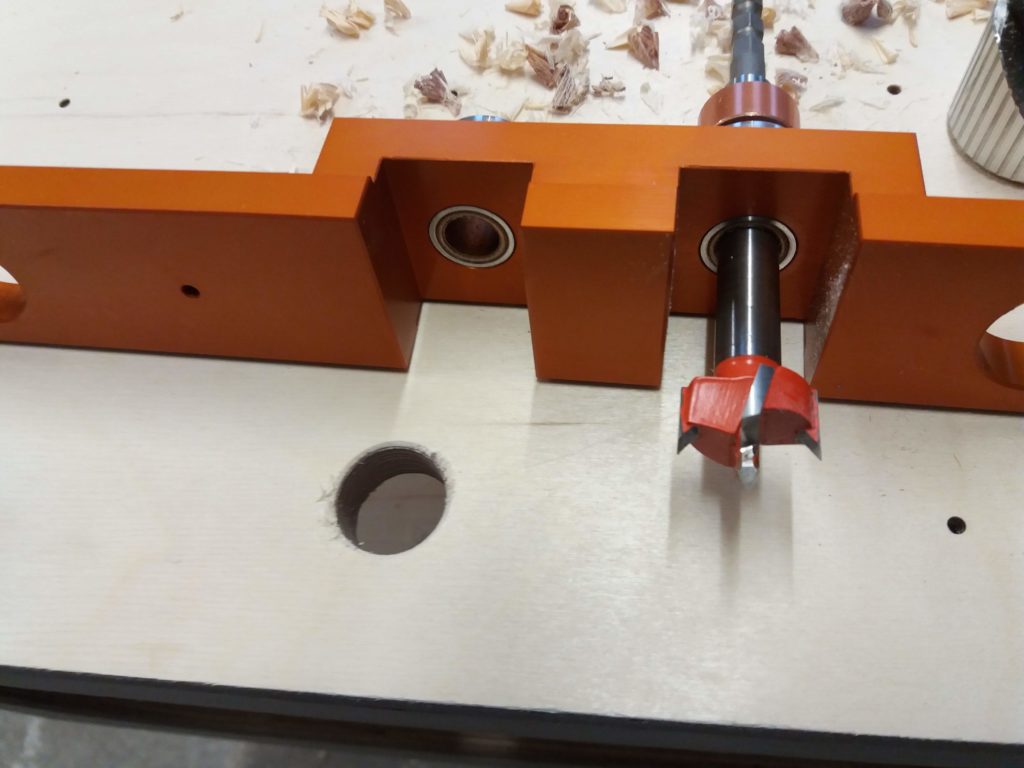

UJK parfguide system jig and 20mm forstner-bit

170 holes drilled! Two parf-dogs show how the holes are used.

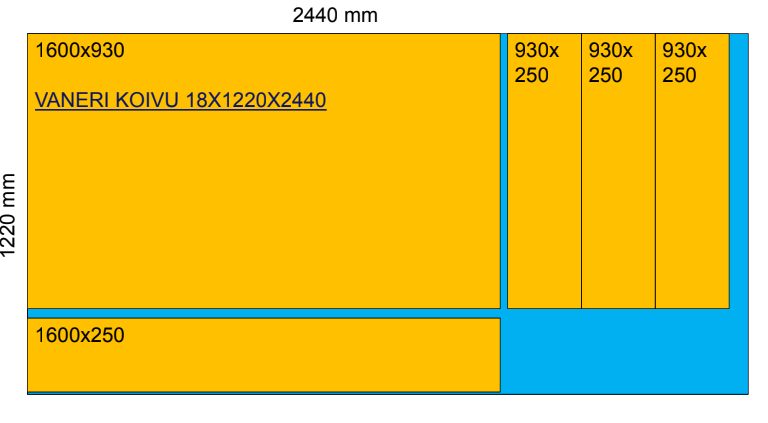

Here's a rough sketch of the dimensions. The dimensions were chosen to fit my workshop, so that it could be built from two 1220mm-by-2440mm sheets, and the dimensions rounded to fit the 96mm-by-96mm parfguide hole pattern nicely.

The pieces needed can be cut from two sheets of plywood, resulting in two top/bottom pieces, two long-sides, two short-sides, and four internal dividers. I only used two of the dividers.

There are a lot of torsion-box or "Paulk workbench" builds out there, here are some links:

- Jay Bates, modified Paulk bench

- Ron Paulk, Paulk work bench

- The naked carpenter, Modified Paulk workbench

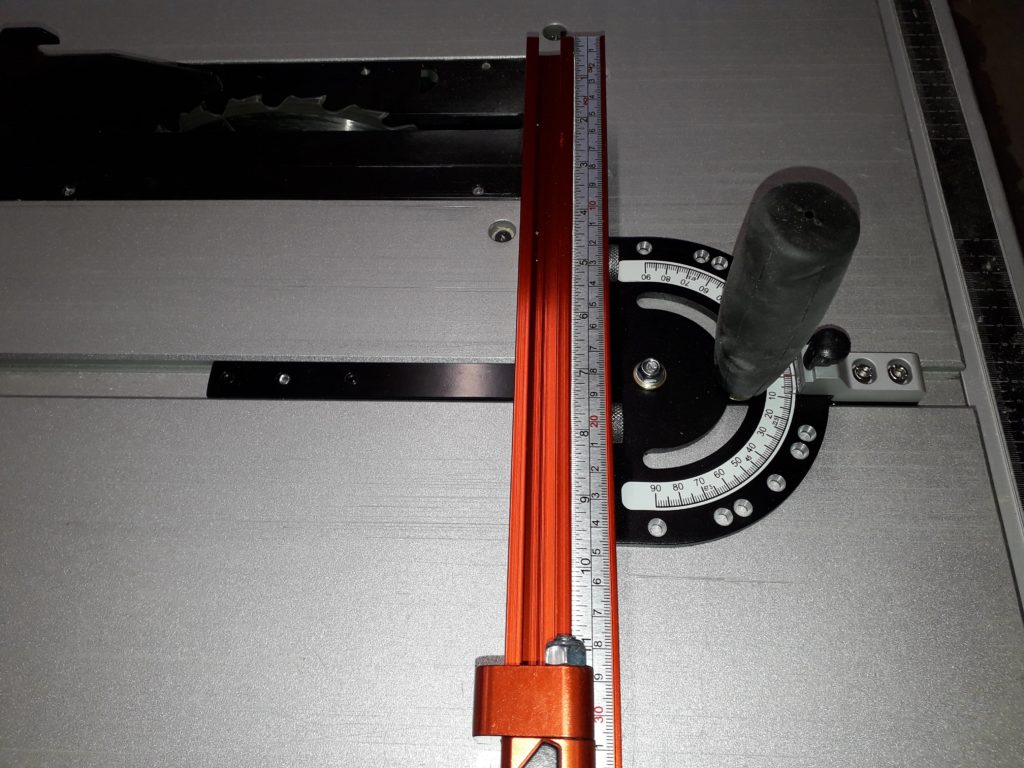

UJK precision mitre gauge fence on Makita 2704 table-saw

Axminster sells this UJK mitre gauge fence, which replaces the stock mitre gauge/fence on my table-saw. The small coin-sized guide at the front needed a bit of filing to fit in the slot of the Makita.

Laser cutting

First try at using the 50W CO2 laser cutter at the Iso Omena library. Material is 4mm Birch ply (K-rauta). I didn't have time to optimize the speed/power settings, so the edge-finish is quite burned, and a flame appears from time to time. There was a 3M tape-film (?model?) available, which when taped over the plywood-to-be-cut should reduce burning and flaming - but I didn't have time to try it.

Workflow: DXF files exported from CAD, the into Adobe Illustrator, set all linewidths to 0.01mm, then save as PDF, then print from Adobe Acrobat to the Epilog printer-driver, set speed/power for the material, send to the machine, set the (0,0) coordinate (top left) for the job, and press Go!

Table saw sled

Table saw sled (for a Makita 2704 saw) from 12mm plywood and pieces of two-by-four. Mostly inspired by Jeremy Schmidt: