I hope to proceed with 800 grit and 1200 grit sanding during the week so that the Pikanto moulds would be ready for baking the first hull over the weekend before Christmas.

Tag: pikanto

Pikanto rudder mould

240 and 400 grit sanding

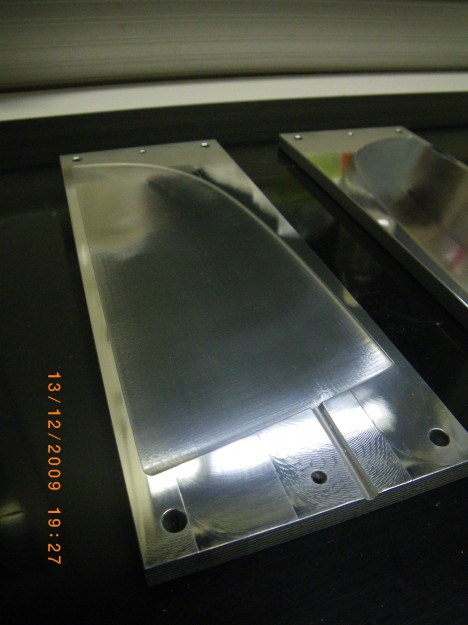

When not shopping online for lathe-electronics/parts I have been busy sanding the Pikanto moulds. First the last bits of 180-grit today, then all over with 240 grit, and finally started with 400 grit which I will have to continue with next in the next session. The flat bits and large gently curved areas of the hull are easy and quick to work with but as always the devil is in the details. The deck mould has a lot of edges and features that are tricky to sand, and all moulds have a sharp 90-degree edge which is easily damaged when handling the moulds.

The plan is to go 600-800-1200 grit next weekend and do a bit of polishing after that.

Pikanto moulds

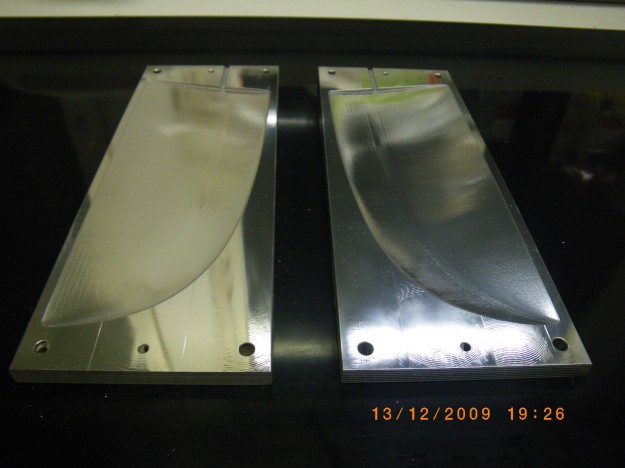

Our three-piece hull/deck-moulds for the Pikanto IOM (designed by Graham Bantock) are now ready. The next step is to sand the surface smooth and polish the moulds. We hope to mould a prototype hull before the new year.

Ultra High Modulus

Pikanto plug painted

The parts of the plug have been glued together, painted, and sanded. We should be ready to lay up the moulds in a few weeks.

Pikanto MDF plug

The final MDF piece for the plug was milled today.

MDF plug pictures

The first half of our Pikanto plug is now milled. The other half will be done next weekend - and then we have a lot of painting and sanding to do before laminating moulds.

Milling MDF

More plug milling

The model yacht plug we're making is milled in three stages. First a rough-cut, then a finish-cut which cuts the plug 1 mm undersize. Then it's coated with a thick layer of tooling gelcoat. What you see above is the final milling pass where the gelcoat is cut down to the final shape. This way we're hoping the final plug will require a minimum of painting/sanding before use.

Lester Gilbert has some new Pikanto pictures on his site. Eventually this project will produce boats like that, but with a deck which is simpler to mould, and with a process we hope to streamline as much as possible.