The PIKANTO moulds were polished first with "Oskar’s buffing and polishing compund M-50" and then with "Norpol Rubbing R-10", both from Terpol (www.terpol.fi) in Turku.

Tag: polish

Shine mould, shine!

After sanding with 1200-grit and a 10-15um particle-size fine paper it is time for polishing. We have two grades of polishing-compound. These pics show the coarse type which is polished with a spinning soft disk on a power-drill.

After polishing follows release agents: first Frekote and then wax. It's still possible we will mould a prototype hull this year. Stay tuned.

Sunday polishing

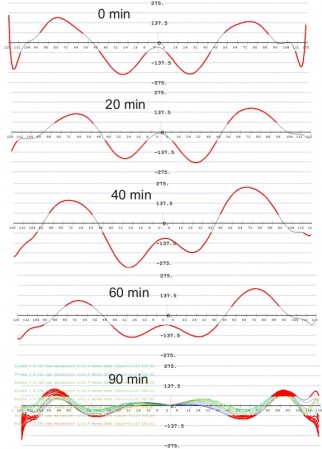

Out pitch-lap is one that really doesn't work when polishing mirror-on-top. Should have realized that yesterday. The first two 20min sessions today were spent making the shape of the mirror worse, before we switched to tool-on-top for the last 30min + 30min. Suddenly it all goes much better, and we are back to a nice better than 1/10 wave sphere. We still see small dots from a laser-pointer reflection, so it's not time for figuring just yet.

The graph shows the wavefront error in nm, compared to a sphere. The Foucault images on the left are simulated from a zernike fit to the surface measurement.

Polishing continues

Something must have been wrong with the pitch-lap on Friday, since we began today with a strange bump in the middle of the mirror. The picture shows how the shape of the mirror (actually the wavefront, compared to a sphere) changed through today's polishing session. Slowly getting back to a good spherical shape. Hopefully the mirror will be polished out soon and we can start figuring it into a paraboloid.

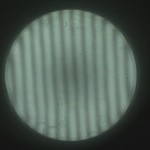

Polishing and Ronchi testing

Polishing is hard work compared to fine grinding. There is much more friction between the lap and the mirror - it's nice to take a break after 15 to 20 minutes of polishing. Possibly due to insufficient pressing our mirror started to polish at the outer edge first. We did about 2 hours of polishing the first evening. Today we started with hot-pressing, i.e. leaving the lap and mirror under hot water for a while and then pressing the two against each other to achieve good contact. After about 1 hour today we did a first Ronchi test, which clearly shows the less well polished spot in the middle. One more hour of polishing and we are up to about 4 h in total. There's still a hint of the less well polished area in the middle. Looking at the Ronchi test the overall shape of the mirror is roughly spherical as it should.

Our Ronchi tester consists of a wooden mirror stand made from plywood with three long M6 bolts to hold the mirror. We're using an LED as a light source, and the 100 lines per inch grating is printed on an overhead-slide with a laser printer.

The radius of curvature is roughly 288 cm indicating a focal length of 144 cm which would make for a focal ratio of F/6.