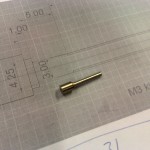

A 31mm long prototype part with 6mm diameter in one end and 3mm at the other. From an M12 stainless steel threaded rod (the only stainless at hand...)

Tag: schaublin

Spindle servo encoder shaft

The 1.75kW spindle-servo for the lathe only has resolver and hall-feedback. So I need to mount an incremental encoder with index pulse on it myself. The rotor for the hall-sensors attaches to the main motor shaft with an M6 bolt. Here I'm making my own M6 bolt with a long 'head'/shaft that will extend outside the back lid of the motor. I cheated a bit by starting with a 0.5" rod which already had an internal M6 thread. An M6 set-screw will form the bolt-part of the shaft, and is also used here to hold the part in the lathe. This was then turned down to ca 11mm to fit the hall-rotor, and 8mm for the part of the shaft that extends outside the motor and to which the encoder will mount.

Encoders are on order from digikey so they should arrive next week.

By taking it slow and measuring a lot the 1949 Schaublin makes parts with tolerances approaching 0.01mm!